Operations

Projects

Colben positions itself as a trusted partner in the production of precision mechanical components and assemblies, employing welded structures, forgings, or rolled products. At the same time, it maintains the production capacity required to carry out subcontracting work, including cast structures.

Highlighted projects

Crusher shaft

| Item | Crusher Shaft |

|---|---|

| Material | Forged 42CrMo4+QT |

| Treatment | Thermal stress relief |

| Machining | Turning / Milling / Gear cutting |

| Dimensions | Ø 340 mm x 4.200 mm Weight 2,5 ton |

| Notes | Component manufactured according to customer specifications Field of application: Recycling Industry |

Spindle Shaft

| Item | Spindle Shaft |

|---|---|

| Material | Forged 42CrMo4 |

| Treatment | Thermal stress relief |

| Machining | Milling / Turning / Deep drilling / Grinding |

| Dimensions | Ø 700 x 1.980 mm. – Weight 2 Ton. |

| Notes | Component manufactured according to customer specifications 100% dimensional inspection with Laser Tracker Field of application: Machine Tools |

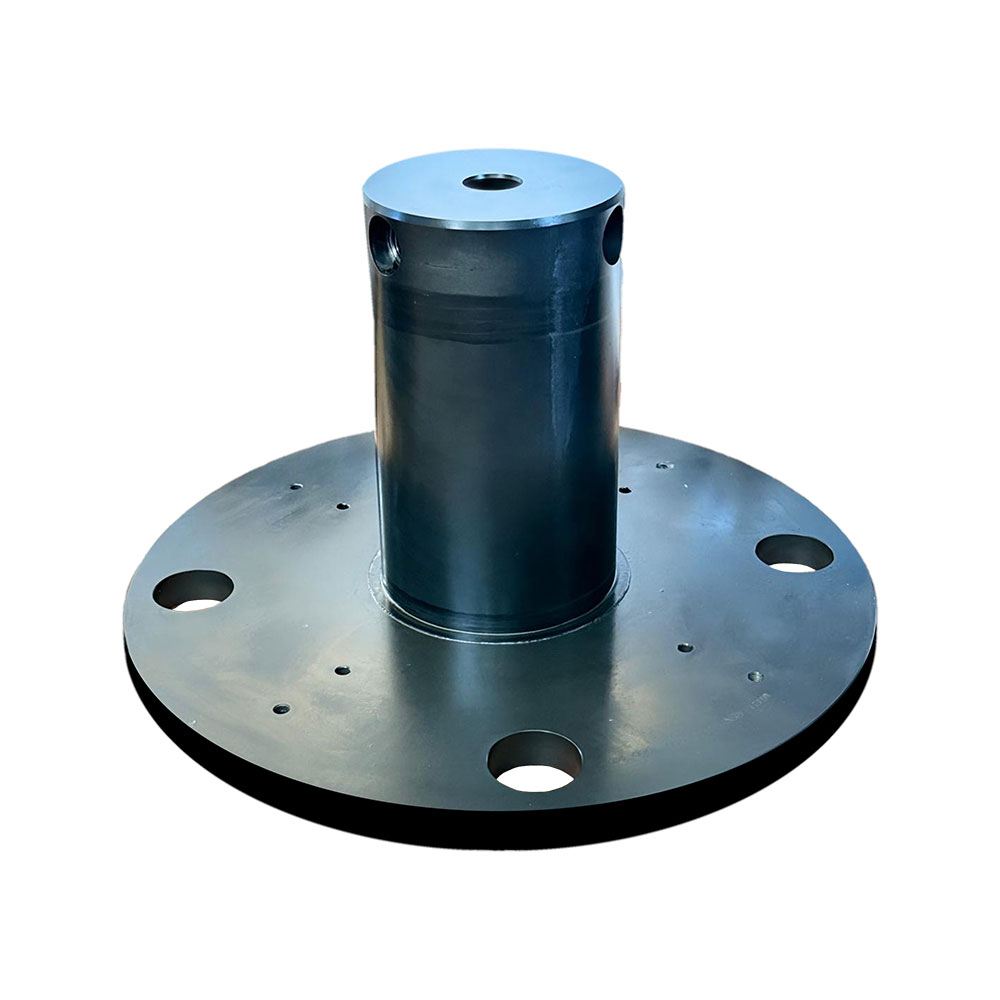

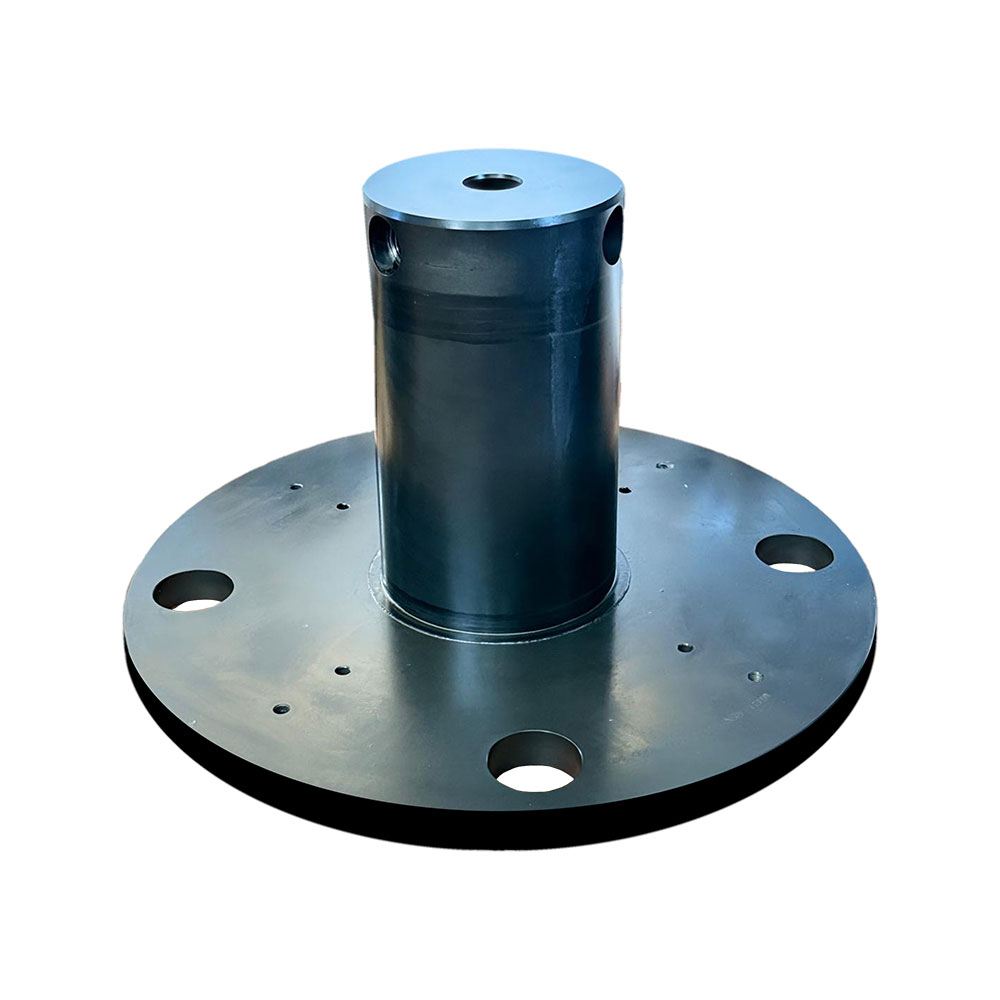

Roller Holder Block

| Item | Roller Holder Block |

|---|---|

| Material | P355NL2 and S355J2+N |

| Treatment | Manganese phosphating / Dry Touch oiling |

| Machining | Turning / Internal drilling |

| Dimensions | Ø 1000 x 600 mm Weight 500 kg |

| Notes | Welded construction machining Dimensional control with Laser Tracker Sector: Oil & Gas |

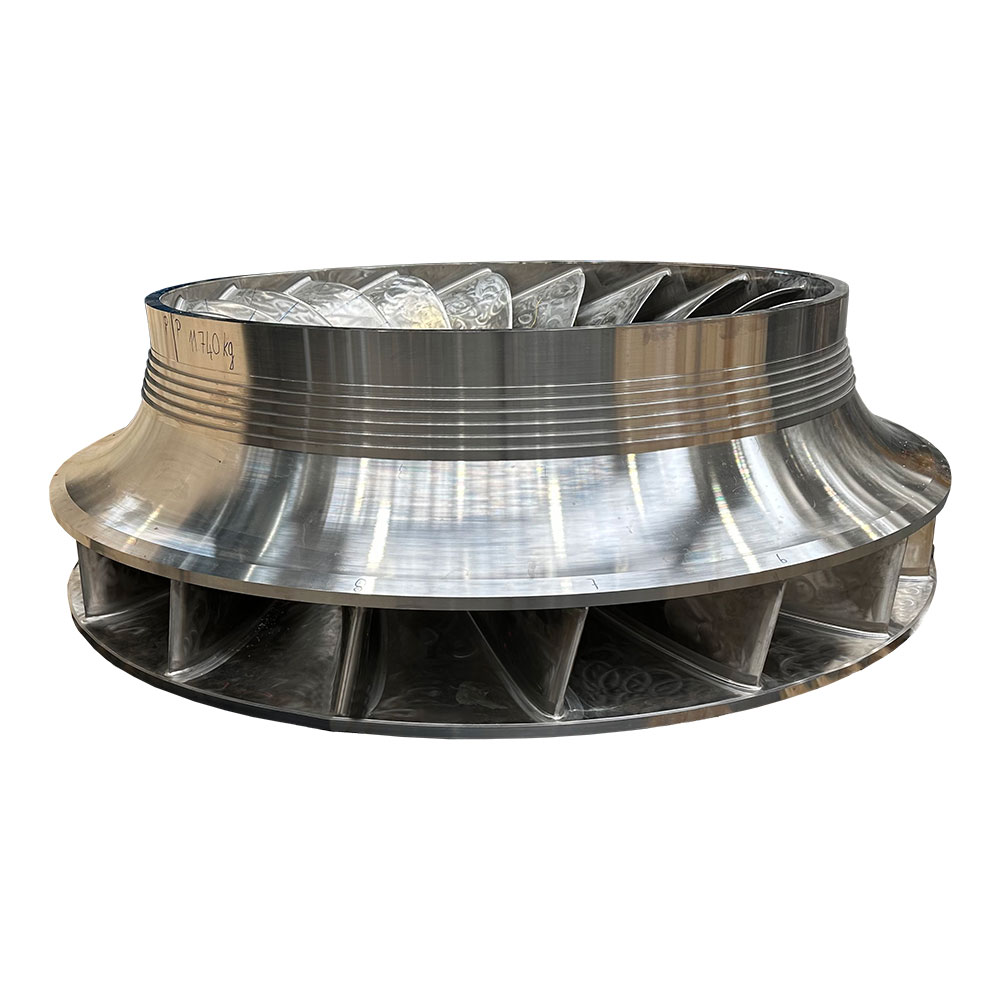

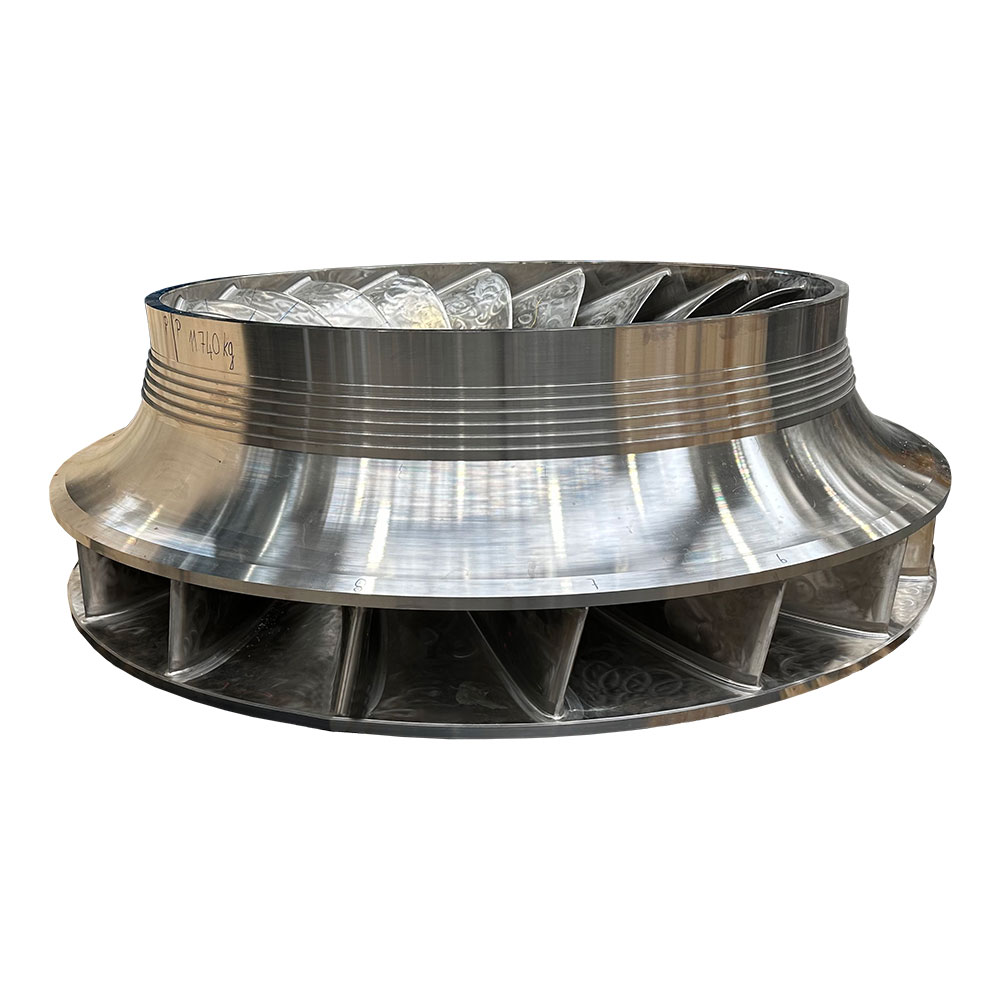

Hydraulic Runner

| Item | Hydraulic Runner |

|---|---|

| Material | GX4CrNi13-4 +QT1 |

| Machining |

Milling of hydraulic profile |

| Dimensions | Ø 2600 mm, finished weight: 6,500 kg |

| Notes | 100% machining according to customer specifications Machining study with preparation of Manufacturing Process Plan and time schedule (Gantt) 100% Non-Destructive Testing: Penetrant Test / Magnetic Test 100% surface inspection with Laser Tracker Mapping of casting defects after machining Static balancing and correction according to ITP Customer inspection 3.2 Documentation preparation Packaging and shipping Field of application: Hydropower |

Expander spindle

| Item | Expander spindle |

|---|---|

| Material | Forged 42CrMo4+QT, according to drawing |

| Treatment | Stress relieving |

| Machining | Milling / Turning / Deep drilling / Grinding Bronze bearings / Final deep boring |

| Dimensions | Ø 700 x 1640 mm Weigth 2 ton |

| Notes | Component manufactured according to customer specifications 100% dimensional inspection with Laser Tracker Field of application: Machine Tools |

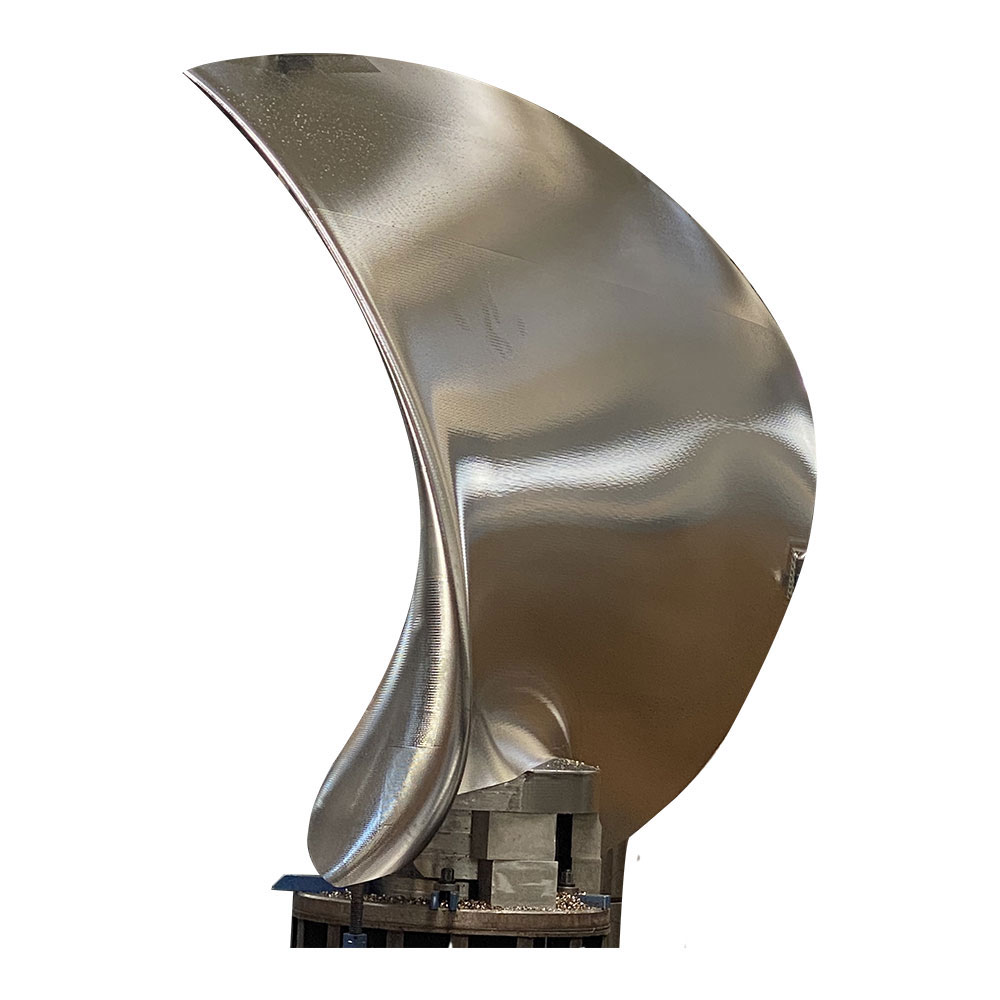

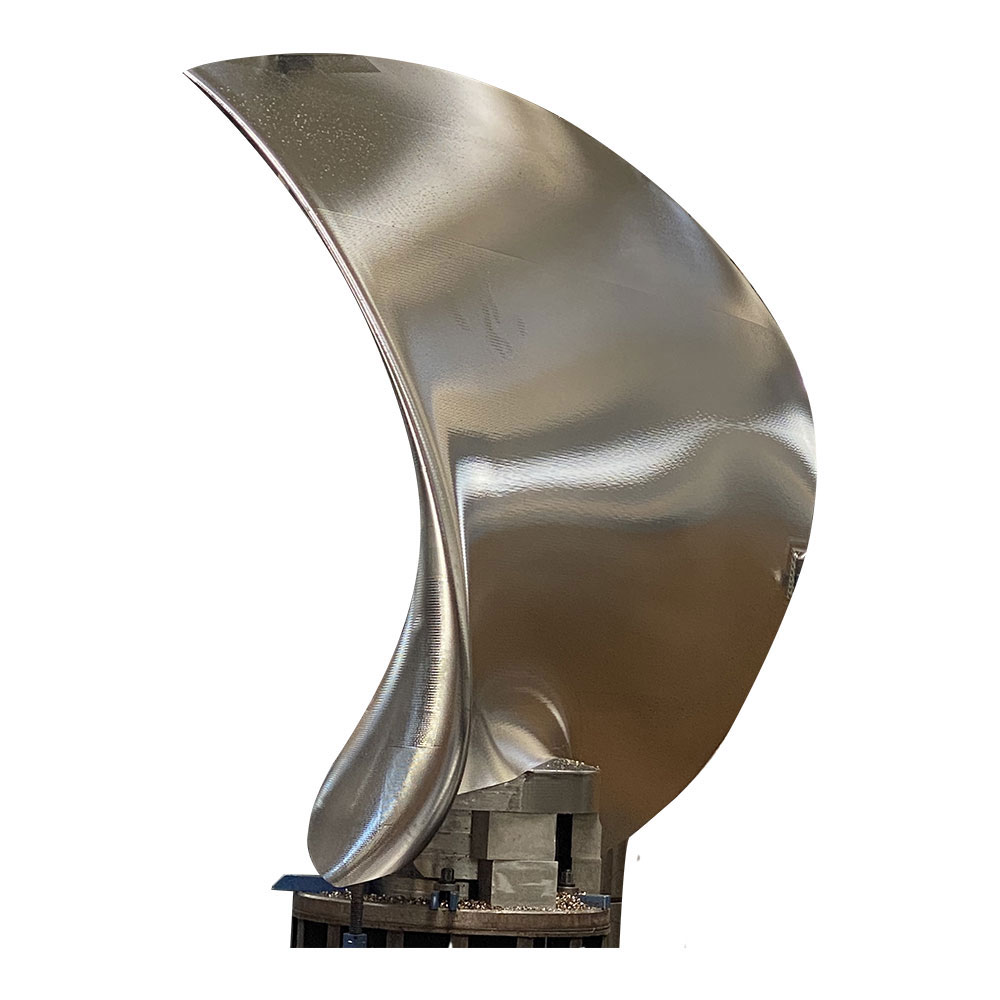

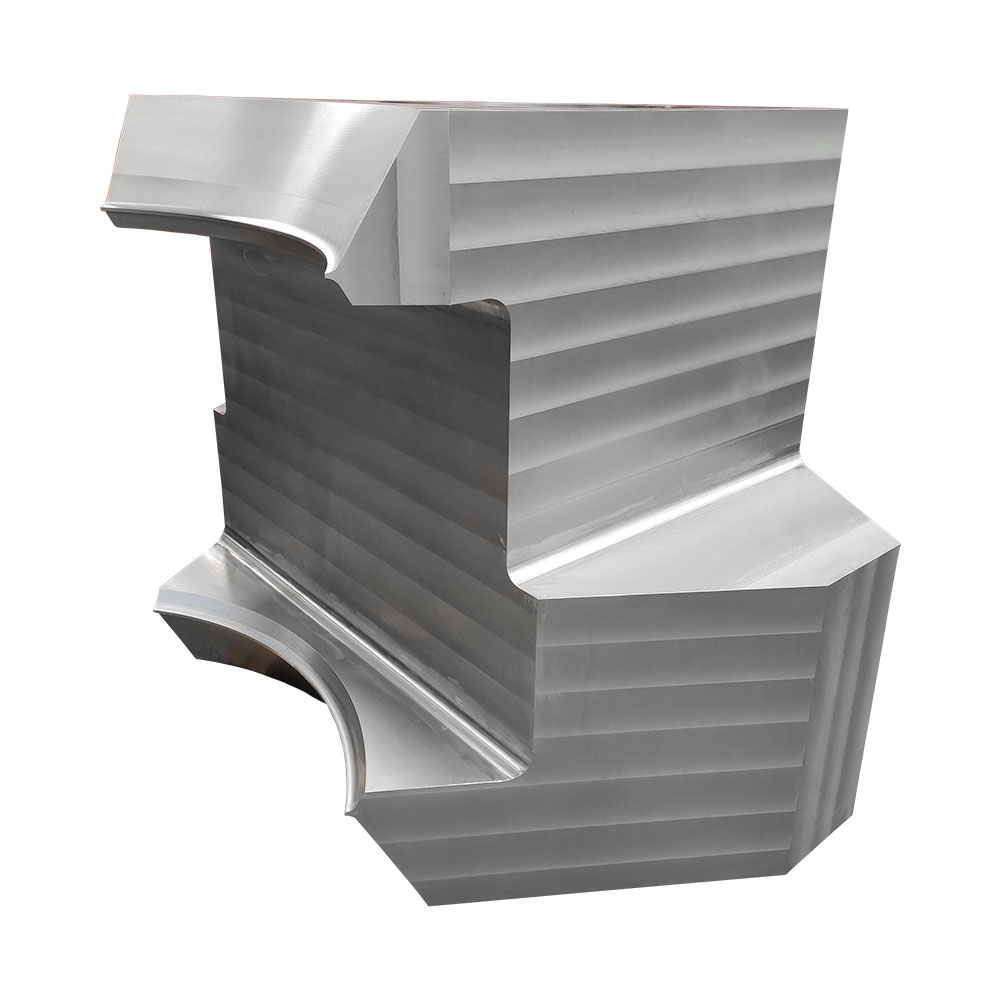

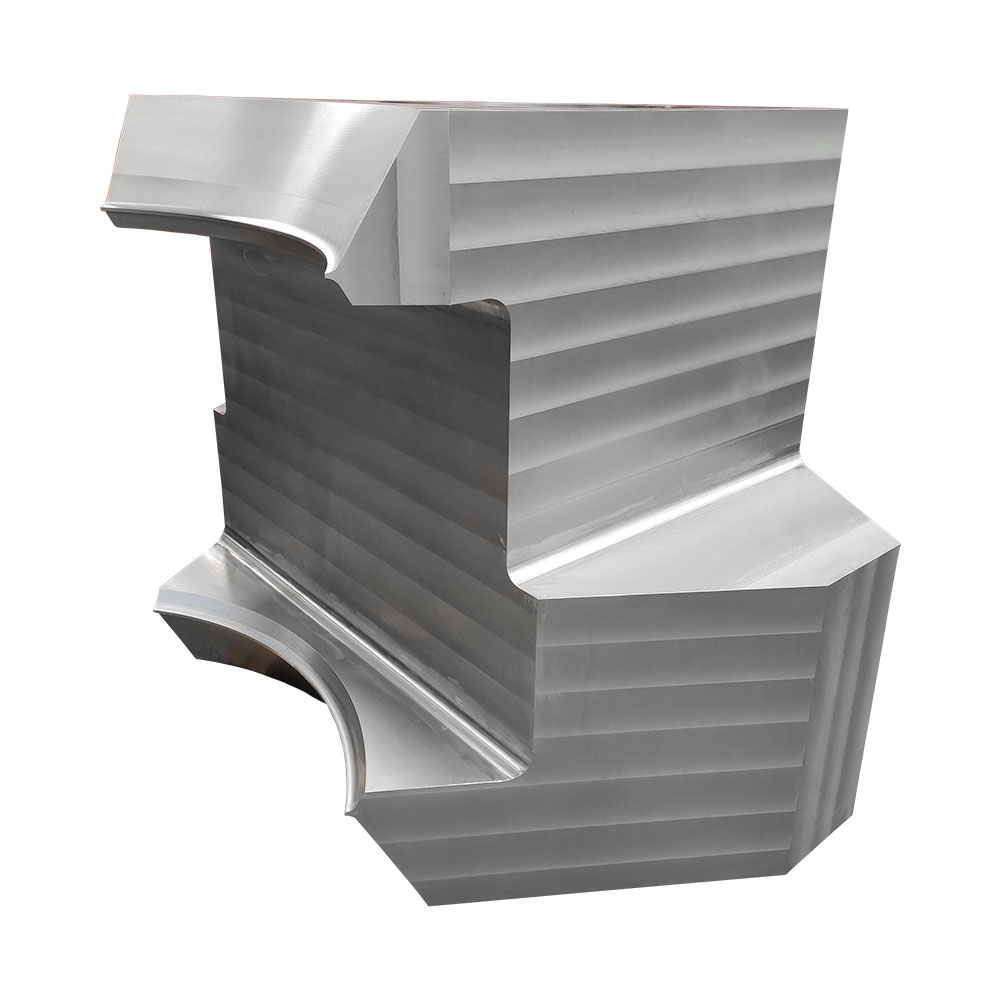

Kaplan blade

| Item | Kaplan blade |

|---|---|

| Material | GX4CrNiMo 13-4 ( I.4317 +QT1) |

| Machining | Mechanical modeling of the hydraulic profile |

| Dimensions | 3700 x 3300 x1200 mm Weight 12 ton |

| Notes | Machining according to customer specifications of a cast part, ground and sandblasted Dimensional surveys carried out with machine tool Field of application: Hydropower |

Welded structure

| Item | Welded structure |

|---|---|

| Material | Stainless steel AISI 304 |

| Treatment | Pickling |

| Machining | Mechanical machining / Cover assembly |

| Dimensions | 2.795 x 1850×328 mm Weigth 274 kg |

| Notes | Component manufactured according to customer specifications Two lateral tanks welded with leak-tight sealing Double leak test at 500 mbar, before and after mechanical machining 100% dimensional inspection with Laser Tracker Dedicated packaging in wooden crate for delicate structure Field of application: Chemical industry |

Auxiliary component

| Item | Auxiliary component |

|---|---|

| Material | AW5083 TO |

| Machining | Milling / Assembly on mechanical group / Post-assembly machining |

| Dimensions | 360 x 200 x150 mm Weigth : 18 kg |

| Notes | Component manufactured according to customer specifications Used for mechanical groups 100% inspection in Metrology Room Field of application: Industrial automation |

Carpentry structure

| Item | Carpentry structure |

|---|---|

| Material | S355J2 +N |

| Treatment | Stress relieving / Sandblasting / Painting |

| Machining | Mechanical machining Manufacturing and assembly of supports Spray painting |

| Dimensions | 6000 x 950 mm Weigth 980 kg |

| Notes | Component manufactured according to customer specifications Welded structure made of tubes, plates, and oxy-cut parts Structural reusable supports designed for transportation to the final customer Dimensional inspection with Laser Tracker Field of application : Industrial automation |

Straightening structure

| Item | Straightening structure |

|---|---|

| Machining | Complete machining on Pama Speedram 1000 |

| Dimensions | 4250 x 3535 x 1.500 mm Weigth 26 Ton |

| Notes | Machining according to customer specifications Dimensional inspection on machine Field of application: Metallurgical industry |

Roller

| Item | Roller |

|---|---|

| Material | S355J2H and S355J2+N |

| Treatment | Chemical nickel plating 20 μm |

| Machining | Welding / Turning / Milling |

| Dimensions | Ø 370×1.600 mm Weigth 600 kg |

| Notes | Component manufactured according to customer specifications |

Pressing end plate

| Item | Pressing end plate |

|---|---|

| Material | S355J2+N, UT tested EN10160 S2F3 |

| Machining | Turning / Milling / Spray painting |

| Dimensions | Ø 1600 x 130 Weigth : 1500 kg |

| Notes | Component manufactured according to customer specifications Field of application: Energy |

Tapered bearing support

| Item | Tapered bearing support – spindle line |

|---|---|

| Material | Forged 42CrMo4+QT |

| Machining | Turning / Milling / Grinding with tapered bearing fitting |

| Dimensions | Ø 650 x 250mm Weigth 155 kg |

| Notes | Component manufactured according to customer specifications Field of application: Machine tools |

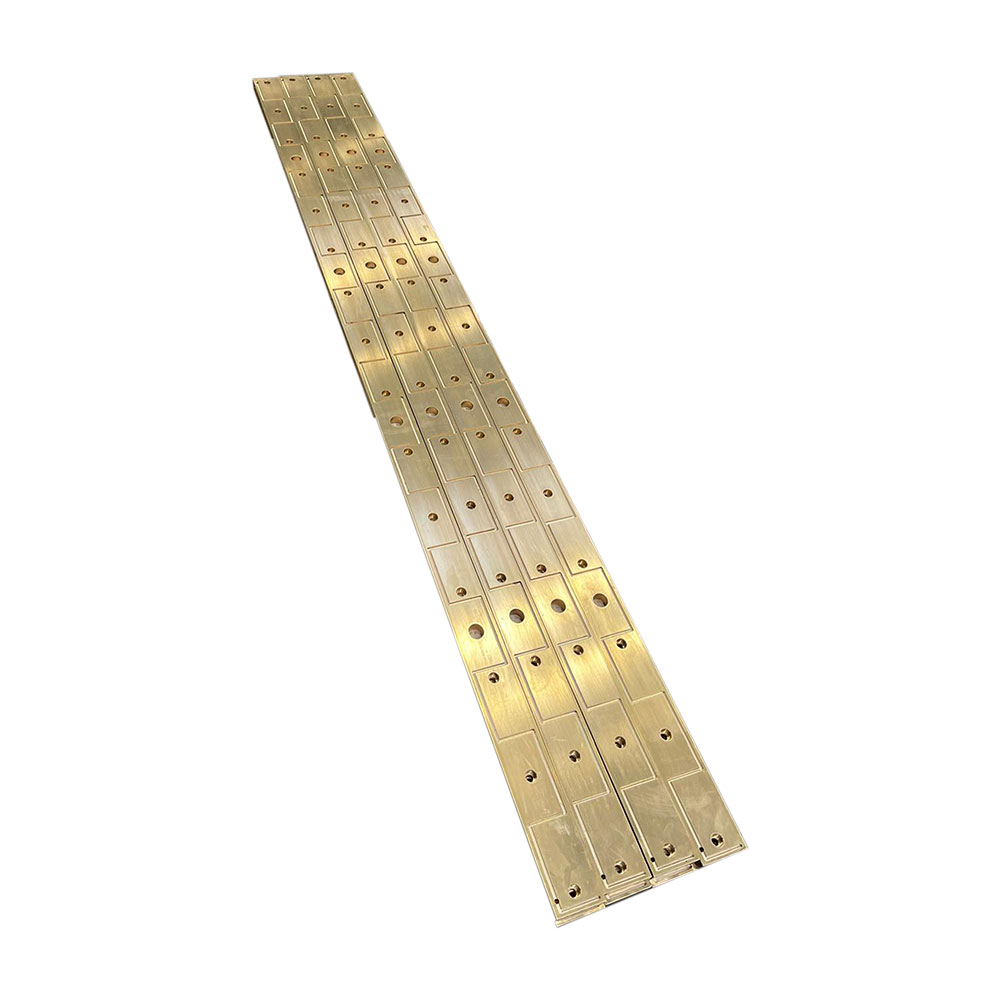

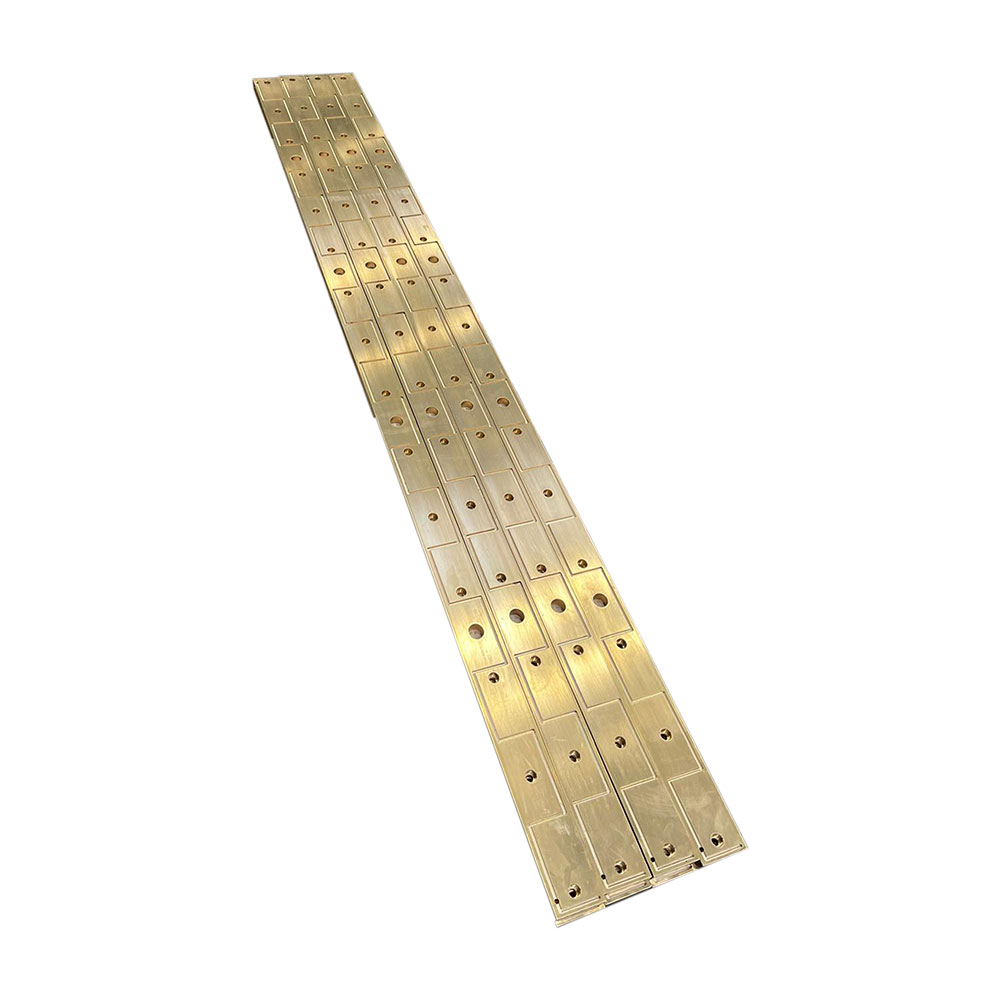

Lubrication pad

| Item | Lubrication pad |

|---|---|

| Material | Brass OT58 |

| Machining | Milling / Polishing |

| Dimensions | 3600 x 60 x15 mm |

| Notes | Component manufactured according to customer specifications Field of application: Machine tools |

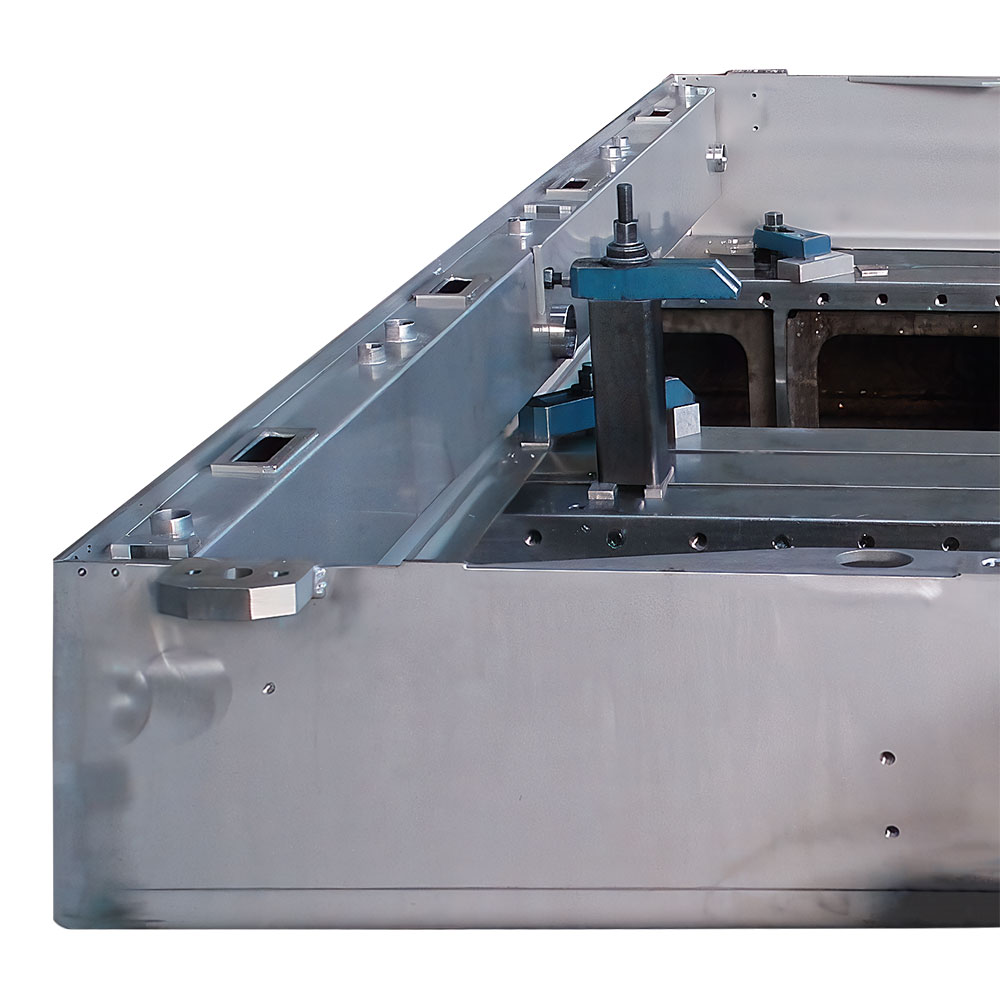

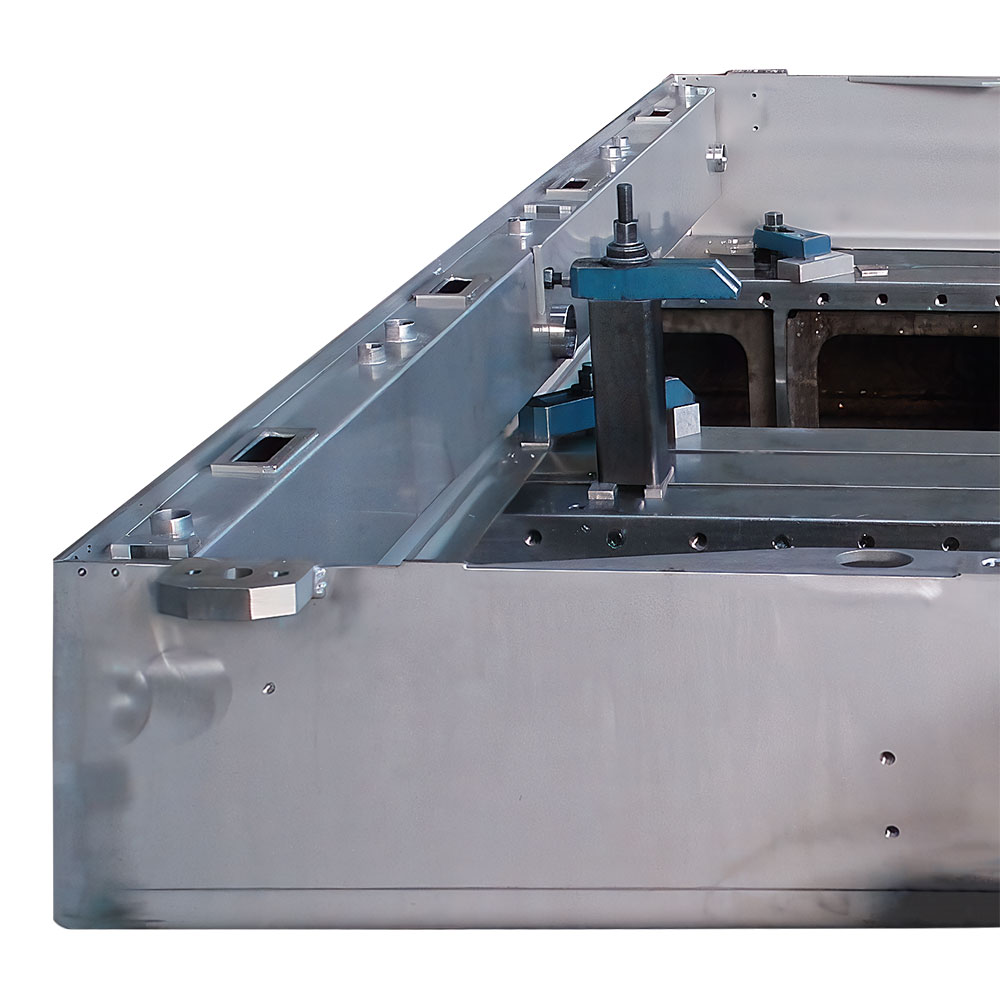

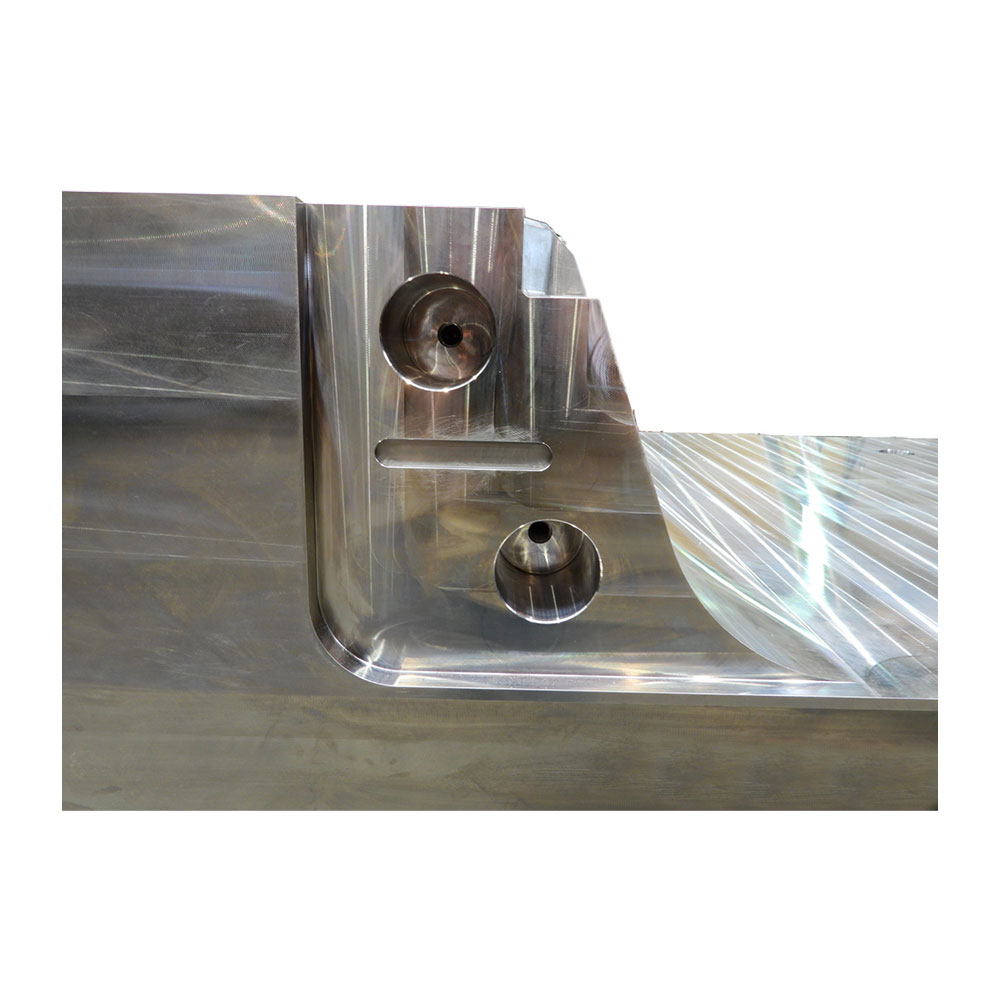

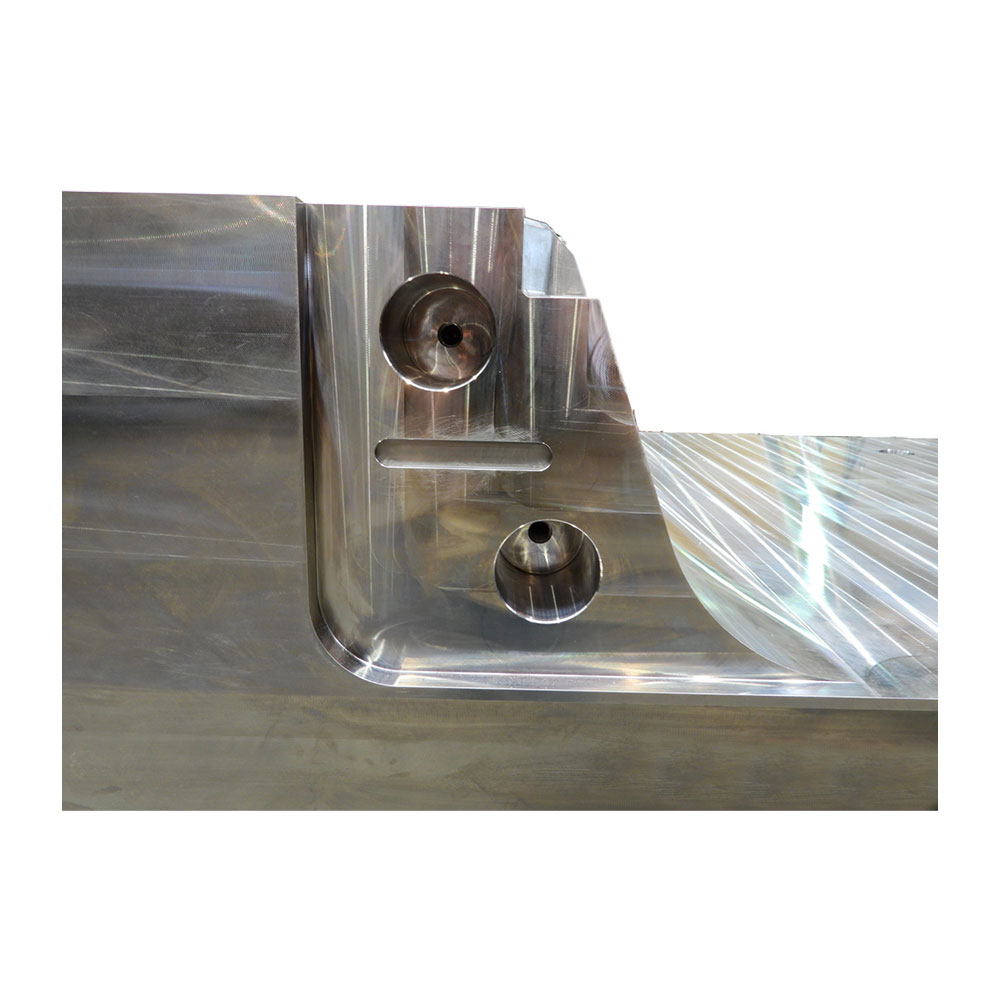

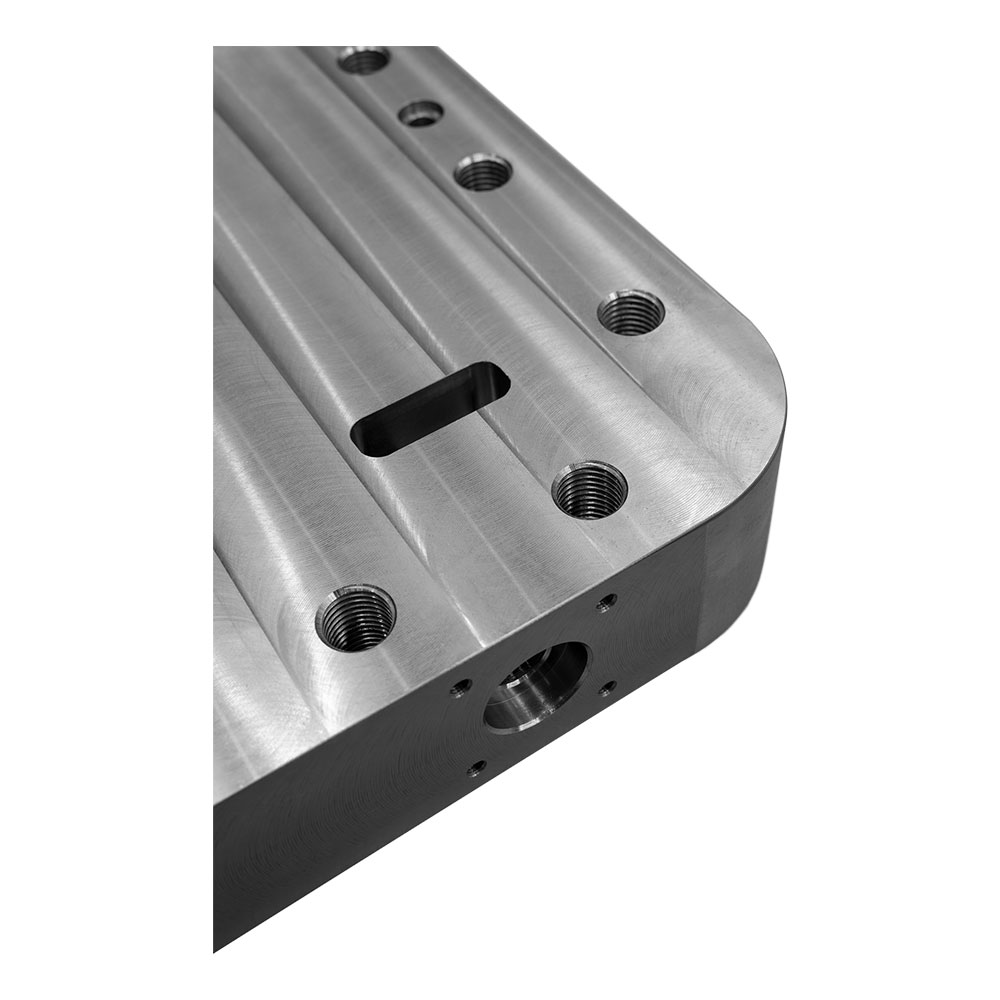

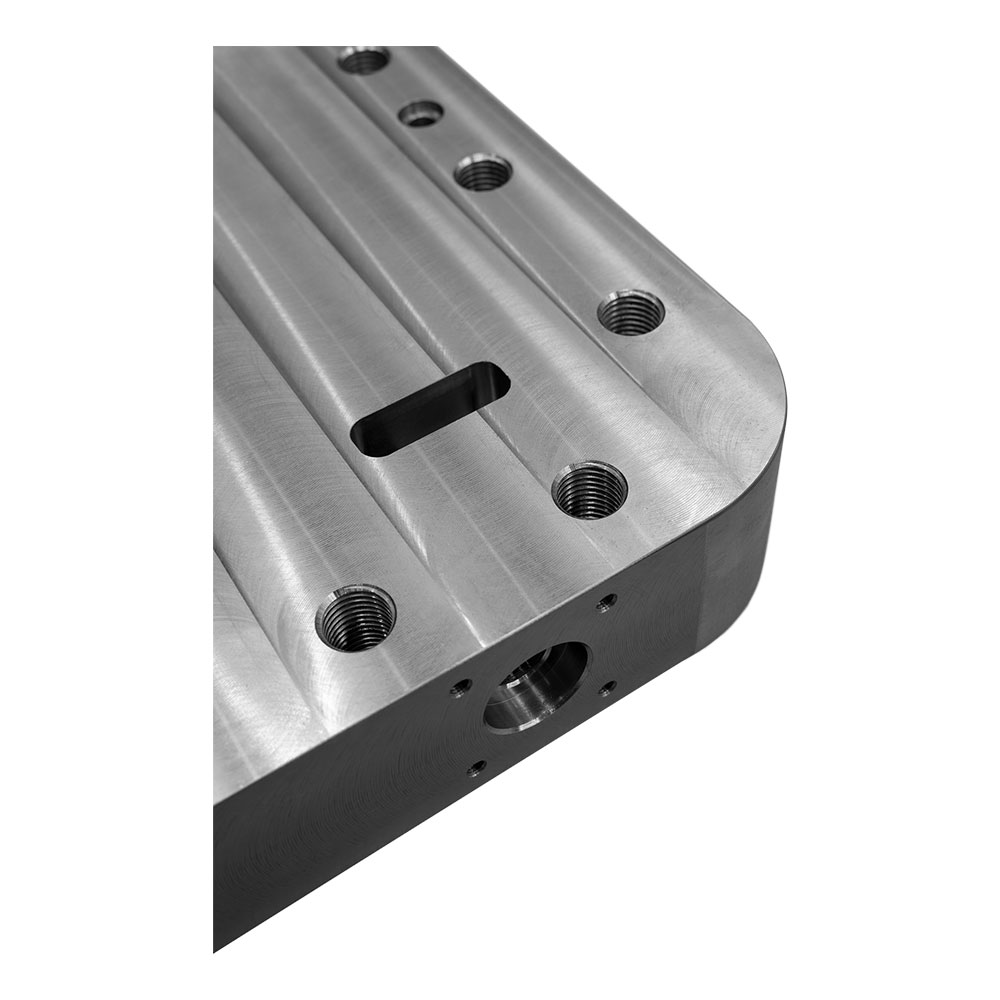

Base frame

| Item | Base frame |

|---|---|

| Material | SA 723 Gr.1 Cl.3 |

| Machining | Milling / Drilling / Polishing |

| Dimensions | 4.200 x 1.300x 420mm Weigth 7 Ton |

| Notes | Machining according to customer specifications Field of application: Machine tools |

Hub component

| Item | Hub component |

|---|---|

| Material | Forged ASTM A266 Gr.4 |

| Machining | Rough machining from solid and finishing |

| Dimensions | 1.500 x 1.120 x 1.150 mm. – Weigth 5,7 Ton. |

| Notes | Machining according to customer specifications Field of application: machine tools |

Shear guide

| Item | Shear guide |

|---|---|

| Material | S355J2+ N / Hardox 400 |

| Machining | Milling / Final polishing |

| Dimensions | 2150 x 390 x 220 Weigth 1300 kg |

| Notes | Machining according to customer specifications Field of application: Metallurgical industry |

Gearbox structure

| Item | Gearbox housing |

|---|---|

| Material | S355J2 + N |

| Machining | Milling |

| Dimensions | 1.350 x 1.200 x 1.070 mm – Weigth 2 Tons |

| Notes | Machining according to customer specifications Field of application: machine tools |

Motor arm

| Item | Motor arm |

|---|---|

| Material | S355J2 + N |

| Machining | Milling / Spray painting |

| Dimensions | 1560x640x50 mm Weigth 160 kg |

| Notes | Component manufactured according to customer specifications Field of application: Machine tools |

End plate

| Item | End plate |

|---|---|

| Material | ASTM A516 Gr.70 |

| Treatment | Chemical nickel plating 70 μm |

| Machining | Milling |

| Dimensions | 880 x 770 x 100 mm Weigth 520Kg |

| Notes |

Component manufactured according to customer specifications |

COLBEN S.R.L.

Fill in the form to make an appointment or request further information.